DLP

For a long time, technology DLP (acronym of Digital Light Processing) - invented and patented by Texas Instruments in 1987 - was the best available for video projection systems.

The image is created by microscopic mirrors arranged in an array on a semiconductor integrated circuit, called a Digital Micromirror Device (DMD). Each small mirror represents one pixel and thus their number corresponds to the resolution of the projected image.

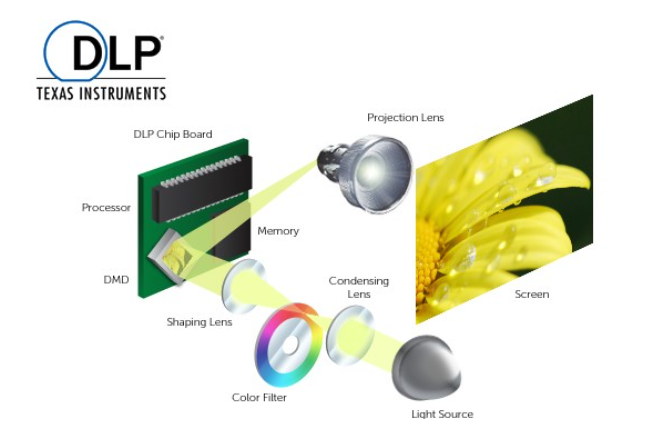

To understand how a single-chip DLP projector works, it may be helpful to view the diagram below, starting with the light source itself:

The light emitted by the lamp is directed through a condenser lens through the red, green, blue and white segments of a colour wheel rotating at high speed.

This creates pulses of coloured light that illuminate the DMD chip and are then reflected by tiny mirrors on its surface to create the image. The human brain combines these red, green and blue sequential images with the white light pulse to perceive colour.

However, some people can distinguish the individual basic colours projected sequentially, instead of seeing the expected colour, and this generates the so-called rainbow effect.

3-Chip DLP

Various systems can be used to reduce or even eliminate the rainbow effect, but the most effective solution is the 3-chip DMD technology, which makes it a more expensive variant of the single-chip DLP technology.

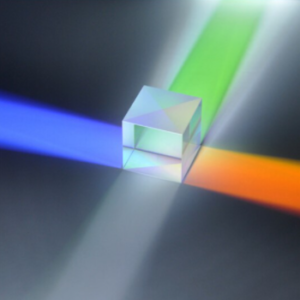

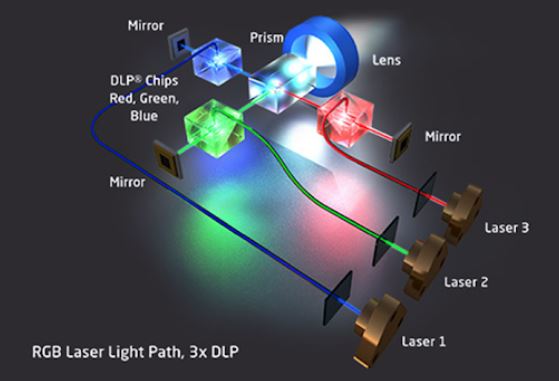

In a 3-chip system, the white light generated by the lamp passes through a prism that divides it into the three components red, green and blue. Each DMD chip is associated with each of the three colours.

The coloured light reflecting from the micro-mirrors is then recombined through a special optical structure, called a dichroic prism, and passed through the projection lens to form a projected colour image of remarkable quality.

LCD (3 LCDS)

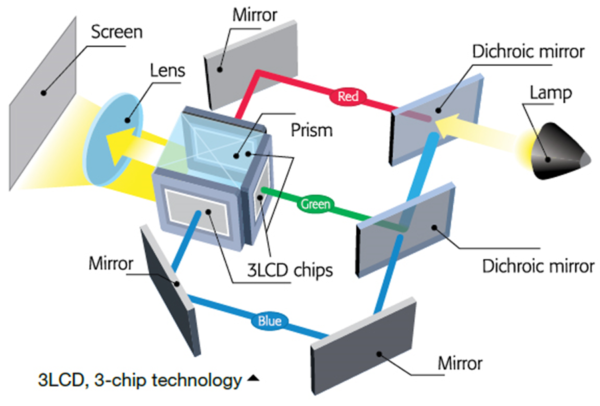

An LCD projector increasingly contains three separate liquid crystal panels, one for each component of the video signal (red, green and blue). The chip, or DMD chips, are here replaced by LCD panels.

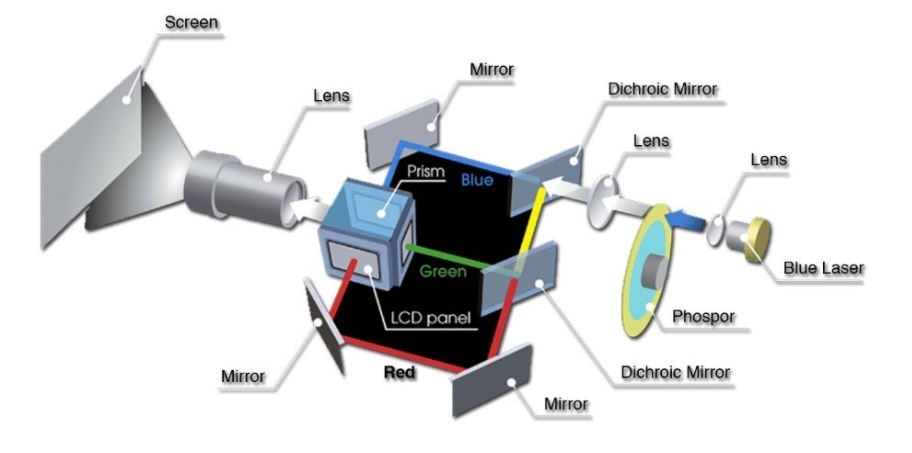

In a triple LCD panel projector, the white light from the lamp is divided into the three basic colours (red, green and blue) using three mirrors. Each of the three streams of light, appropriately channelled to the respective LCD panels, passes through them to create the red, green and blue image components, which are then recombined through the usual dichroic prism, prior to projection, to form one complete colour image.

LCoS and its variants

LCoS, which stands for Liquid Crystal on Silicon, is a newer technology than those mentioned so far; it was created to solve both DLP and LCD technology problems.

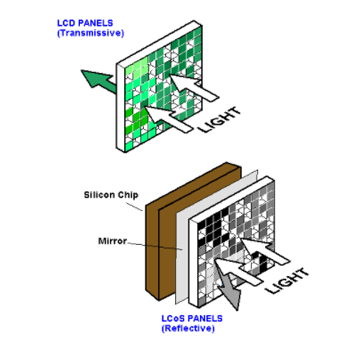

This is a miniaturised active matrix liquid crystal display, also known as a micro-display, which uses a liquid crystal layer on top of a reflective silicon backplane.

Unlike the LCD panels used in single- or triple-chip projectors, LCoS panels work by reflection.

This technology is more expensive than those seen so far, but also offers a number of advantages. The D-ILA (acronym for Digital Direct Drive - Image Light Amplifier) projector developed by JVC and SXRD (acronym for Silicon X-tal Reflective Display) developed by Sony represent a particular implementation of LCoS technology.

From lamp to solid-state lighting sources (SSI)

The technologies described so far, i.e. DLP and LCD, have traditionally always had in common the same light source, the lamp, a fundamental element in video projectors.

Over time, more reliable solutions were considered, as the lamp is a component that is obviously subject to wear and tear, and its average life varies between 2000 and 6000 hours, while the cost is between 200 and 500 Euros, in some cases even more.

This is why, in the course of time, illumination by means of a laser source was introduced.

The first projectors of this type used a blue laser and had limitations in the fidelity of colour reproduction, which limited their field of use to text-based corporate presentations. Over time, RGB laser projectors were developed that extended the field of possible applications to the most critical sectors, where excellent colour rendition is required.

In the drawing above, the phosphor wheel is used to generate white light, which is then broken down into the three RGB components addressed, by means of a series of mirrors, to the three LCD panels. In the solution below, three different independent laser beams were used:

A laser light source has the advantage of low energy consumption compared to conventional lamps and requires replacement after approximately 20,000 or even 30,000 hours, a much longer time interval than any projector lamp.

Compared to conventional lamps, laser start-up is virtually instantaneous and brightness remains constant throughout the life cycle of these products. And best of all, mercury-free laser technology requires no specialist handling or disposal at the end of its life cycle.

Hybrid solutions using both laser and LED sources have also been investigated since 2010.